Houston Garbage Disposal Installation: Permits, Codes, and Safety

A garbage disposal seems simple from the outside. Flip a switch, grind the scraps, move on with your day. In a Houston kitchen, though, it sits at the intersection of plumbing, electrical, and local code. That’s where installations get messy, and why a straightforward swap can turn into a morning of surprises. I’ve installed and repaired disposals in bungalows in the Heights, new builds in Spring Branch, and mid-century townhomes off Westheimer. The technical steps are familiar, but the details change house by house: trap alignment that doesn’t line up, GFCI requirements in older kitchens, dishwashers sharing the wrong branch, or a builder-grade sink flange that leaks under load.

If you understand how Houston regulates this oddly complex little appliance, you stand a better chance of a clean, quiet install that doesn’t leave a slow drain, a tripped breaker, or an inspector’s red tag.

What the codes actually say in Houston

Houston enforces the City of Houston Construction Code, which adopts and amends national model codes. For a disposal, the plumbing rules generally trace back to the Uniform Plumbing Code or International Plumbing Code as adopted locally, and electrical rules to the National Electrical Code. The city’s amendments matter. They change thresholds, sometimes the hardware, and how inspectors interpret gray areas.

On the plumbing side, the disposal counts as a fixture attached to the sink’s tailpiece. That means the trap, trap arm, vent, and discharge all fall under code scrutiny. Houston expects a P-trap installed at the same elevation as the sink outlet, with a continuous slope on the trap arm to the branch. No S-traps and no double trapping. If you tee a dishwasher into the disposal, you need the manufacturer’s designated dishwasher inlet and a proper air gap or a high loop per local interpretation. In some neighborhoods, inspectors are still strict about air gaps for dishwashers draining through the disposal. If you are pulling a permit, ask your inspector about their preference. A two-minute conversation can save you a callback.

On the electrical side, disposals need a dedicated branch circuit in many scenarios, and either a cord-and-plug connection with a receptacle under the sink or a hardwired connection in a junction box with a listed flex whip. Houston follows the NEC requirement for GFCI protection in kitchen areas. If the disposal is cord-and-plug connected on a countertop circuit, that receptacle usually needs GFCI. If it’s hardwired on a dedicated circuit, the protection can be at the breaker in the panel. In remodels, GFCI and sometimes AFCI come into play, especially when walls get opened or circuits are extended.

One more city-specific wrinkle: Houston’s code tolerates existing conditions within limits. If the installation is a like-for-like swap with no new wiring and no new drain configurations, you may not trigger a full code upgrade. If you run new cable, cut into the wall, or reconfigure the trap or venting, you step into permit territory and, by extension, into full compliance. What counts as “like for like” can be a judgment call. If you are unsure, a quick check with the Houston Permitting Center saves time and money.

Do you need a permit for a disposal in Houston?

For a simple replacement, many homeowners skip a permit. They remove the old disposal, hang the new food waste disposer troubleshooting one, connect a cord, and keep the existing drain and electrical. In practice, inspectors prioritize higher-risk work. Still, the city’s rules say plumbing and electrical alterations require a permit unless they fall under specific exemptions. A true like-for-like replacement, same horsepower, same connection type, and no alteration to drain or wiring, typically falls into a gray area that most trades treat as exempt.

Change the wiring or plumbing, and you are in permit land. Examples: converting from hardwired to cord-and-plug, adding a GFCI receptacle under the sink, running a new circuit, reconfiguring the trap because the new disposal outlet doesn’t line up, or adding a dishwasher branch and air gap. Licensed contractors can pull same-day over-the-counter permits online through the city’s portal. Homeowners who occupy the home can often pull their own permits too, but check the current rules because Houston adjusts them from time to time.

Fees are modest for a single-trade permit. Expect electrical and plumbing permits each in the tens to low hundreds depending on scope. The bigger cost is time. Scheduling inspections can add a day or two. If the job is straightforward and you are already opening walls for a remodel, bundling the disposal work into the larger permit usually makes sense.

Safety starts before the packaging comes off

Most disposal issues I’m called to fix start at the planning stage. A contractor walks into a job with a unit they like, not the one that fits the sink and drain geometry in front of them. The result is a trap that sits too high, or a dishwasher hose that dips and creates a siphon. Spend five minutes measuring before you buy anything.

Look under the sink. Note the centerline of the sink outlet, the height of the wall stub-out, and the distance from the centerline to the wall. Measure the interior cabinet height and depth. If the wall stub-out, measured from the bottom of the cabinet, sits at 6 to 7 inches and your disposal outlet will be lower than that, you’ll end up with a trap that climbs uphill. That’s a guaranteed slow drain. You either need a disposal with a higher discharge, an offset flange, or you need to lower the wall stub. Lowering the stub means opening the wall and possibly adjusting the vent, which turns a quick install into a mini remodel.

Check power next. Pull the access cover under the sink. If you see a receptacle in the back wall fed by a cable that looks newer than the home, you probably have a cord-and-plug setup. If you see a metal-clad whip disappearing into a junction box with wirenuts, you’re hardwired. If the switch on the backsplash does nothing, trace it. Sometimes I find disposals wired through the dishwasher circuit or tied into a lighting circuit, both of which cause nuisance trips.

Ventilation matters too. A disposal does not replace the need for a proper vent. If you find an air admittance valve under the sink in a Houston home, confirm it’s listed and allowed under the current city rules for that type of drain and configuration. In older homes with marginal venting, a high-performance disposal can overwhelm the trap seal if the plumbing isn’t right, pulling air and leaving a rotten-egg smell.

Choosing the right unit for a Houston kitchen

I’ve installed models from a quarter horsepower all the way to one horsepower in big family kitchens. For a typical Houston household, half to three-quarters horsepower is the sweet spot. It handles fibrous scraps, egg shells, and the occasional forgotten spoon without rattling the sink off the counter. Heavier cast stainless grind chambers last longer in humid Gulf Coast conditions than light aluminum housings, which corrode faster when a leak goes unnoticed.

Noise ratings matter in open-plan homes. I’ve stood in Montrose living rooms where a builder’s budget disposal turned a quiet dinner into a shout-fest. Better models suspend the motor with rubber isolators and line the grind chamber to dampen vibration. If you have a thin-gauge stainless sink, any disposal will amplify sound. A thicker sink or a rubberized sound mat helps.

Pay attention to discharge height, body diameter, and mounting system. Many homes in Houston use a standard 3-bolt mounting ring that plays nicely with existing sink flanges. If the old flange is pitted or the putty has turned to powder, replace it with the manufacturer’s flange and fresh plumber’s putty. For stone or composite sinks, use the manufacturer-recommended sealant. Some require silicone rather than putty to avoid staining.

If you run a dishwasher, make sure the disposal has a capped dishwasher inlet. Knock the cap out only after the disposal is mounted, then fish the metal slug out of the chamber so it doesn’t jam the impeller on first start. I’ve been back to fix that more times than I’d like to admit when someone forgot to remove the slug.

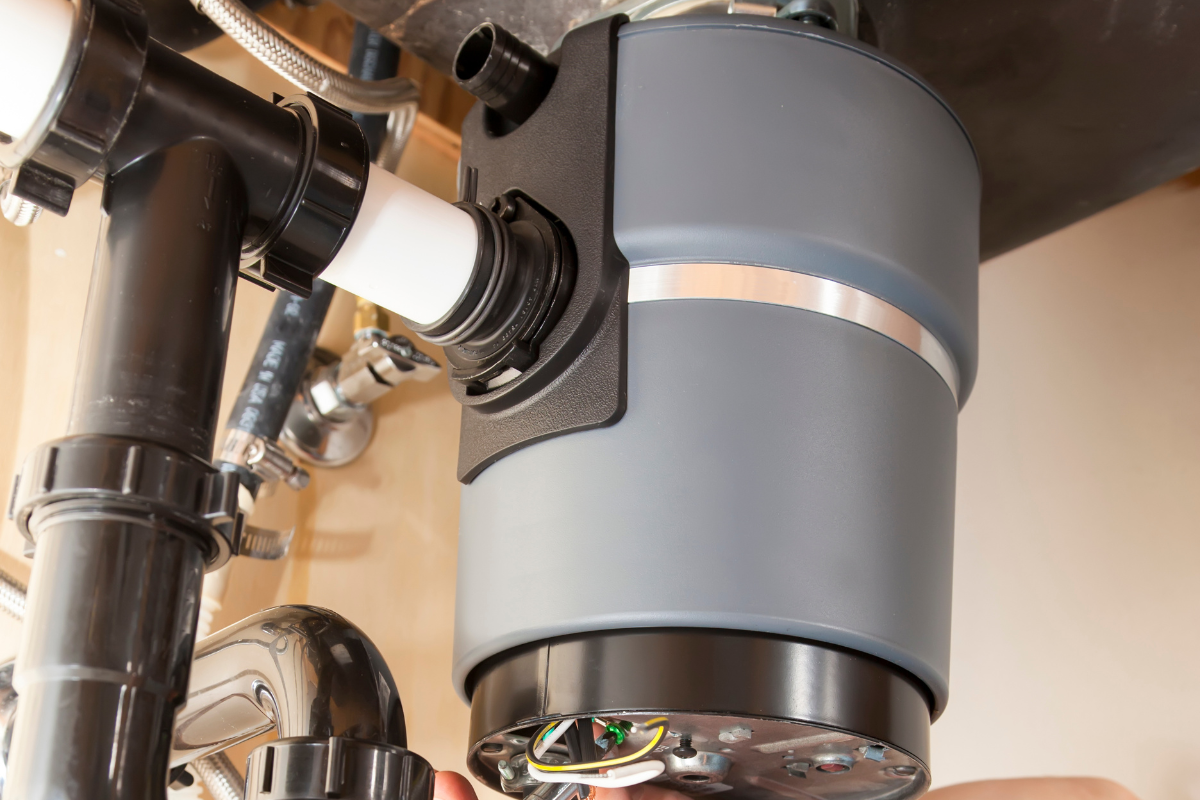

The installation workflow that avoids callbacks

I teach apprentices the same rhythm for every install. It makes for quiet, leak-free results. Here’s the concise version that respects both plumbing and electrical safety.

- Confirm power off with a non-contact tester and verify the correct circuit at the panel. Test the switch. If hardwired, lock out the breaker. If cord-and-plug, unplug and tag the cord.

- Dry-fit the disposal, trap, and dishwasher hose before any sealant. Check discharge height, trap alignment, and hose routing to an air gap or high loop under the counter.

- Set the sink flange with fresh putty or specified sealant, snug the mounting ring evenly, and wipe squeeze-out. Let it set a few minutes so it doesn’t slide when you hang the unit.

- Wire the unit per listing. For hardwire, use a proper strain relief and bond the ground. For cord-and-plug, install a listed cord kit and a GFCI-protected receptacle if required.

- Run a fill-and-drain test with dyed water and a sink stopper. Check for weeps at every joint under static pressure, then run the disposal with cold water and recheck.

That list glides over a lot of micro-decisions. On the discharge, I prefer a rigid tailpiece into a slip-joint P-trap instead of flexible accordion tubing. Accordion hose is a clog factory and collects grease at every rib. Keep the trap arm level or slightly sloped toward the wall stub. No dips that hold water beyond the trap seal. If the stub sits too high, don’t cheat the trap upwards to meet it. Either choose a higher-discharge disposal or rework the stub.

Dishwasher drains in Houston present real variation. If the counter layout allows, I still use a countertop-mounted air gap to keep inspectors happy and to reduce backflow risk. If aesthetics rule, a high loop mounted to the underside of the countertop with a secure clip is the next best thing. Keep the loop firmly at or above the flood rim of the sink.

Electrical connections deserve the same rigor. If you find a receptacle under the sink that is not GFCI and your jurisdictional interpretation requires it, replace it with a GFCI or install a GFCI breaker at the panel. Check that the box is large enough for the conductors and device. If hardwiring, use a listed flex whip of appropriate length, not lamp cord or open NM cable dangling in the cabinet. Bond the ground to the green screw on the disposal’s housing.

Common code pitfalls I see around Houston

The top failures are predictable. Trap too high relative to the wall stub, causing water to sit and food solids to settle. No air gap or proper high loop on the dishwasher hose, which allows dirty water to burp back into the dishwasher. Lack of GFCI protection when required. Unsupported wiring and missing strain sink flange replacement relief where the cord enters the disposal’s junction box. And a classic: forgetting to remove the dishwasher inlet knockout, which floods the cabinet on the first dishwasher cycle.

There is also the quiet leak that shows up a week later. If you reuse an old sink flange, the putty ring can be fatigued. It might hold during your test, then seep under the constant vibration of the motor. If a homeowner reports a musty smell days after install, I bring a bright light and a dry paper towel to trace it. The water line often lies at the back of the flange or the tailpiece slip nut.

Another pitfall is mismatched metals. If you have a cast iron sink and install a stainless flange, you won’t create galvanic fireworks under a normal kitchen environment, but if a constant weep introduces minerals and a slight current, corrosion accelerates. Cleanliness and proper sealing are your best defense.

When a simple replacement becomes a small remodel

Newer disposals are often taller than the units they replace, especially if you upgrade horsepower or noise insulation. In many Houston homes built in the 70s and 80s, the sink stub-out sits higher because the original unit was short. If your new disposal outlet sits below the centerline of the wall stub and you cannot achieve proper trap geometry, you are in the land of lowering the stub. That means cutting open the back wall of the cabinet, sweating or gluing new fittings, and sometimes adjusting the vent tie-in. It also means a plumbing permit and an inspection.

Electrical upgrades can trigger similar scope creep. If your kitchen circuits have no GFCI protection, the inspector may require you to bring the disposal circuit up to current code if you modify it. That could be a GFCI breaker, which is straightforward if your panel accepts it, or adding a GFCI receptacle under the sink if you are on a cord-and-plug configuration. If the existing wire gauge is undersized for the breaker, you’ll need to correct that too.

In these cases, a professional crew familiar with Garbage disposal installation Houston wide can finish in a day, including patching the cabinet back and leaving a clean workspace. A homeowner can do it with patience, but factor in two to three trips to the supply house and time to coordinate the inspection.

Safety habits that pay off

Use eye protection when you knock out the dishwasher plug. That metal slug can shoot out with surprising energy. Support the disposal while mounting. Larger models weigh 12 to 20 pounds. An off-center lift can crack a thin porcelain sink flange. I sometimes stack a couple of wood blocks and a folded towel under the unit to hold it while I align the mounting ears.

Only run cold water during testing and grinding. Hot water can soften fats that later re-condense and glue themselves to the trap and drain. It’s better to keep fats congealed and moving. Teach the household to feed scraps gradually. A disposal is not a wood chipper. Celery, artichoke leaves, and onion skins can wrap around the impeller and stall the motor if stuffed all at once. Rice and pasta swell and clog traps. Coffee grounds are fine in small amounts if the trap is right, but they pile up in accordion hoses and poorly sloped arms.

Keep a proper hex wrench in a kitchen drawer. Most disposals accept a 1/4-inch Allen key at the bottom to free a jam. Kill the power, crank the impeller back and forth, and retrieve foreign objects with tongs, not fingers. If the reset button on the bottom trips repeatedly, the motor is overheating or there’s a partial jam. Continuing to reset without diagnosis shortens motor life.

Where Houston climate and water quality show up

Houston’s humidity drives mold growth in neglected cabinets. Any small weep under the sink becomes a musty mess quickly. After installation, I leave the cabinet doors open for a few hours to let moisture dissipate. If there’s a history of leaks, I recommend a shallow drain pan and a battery water alarm. They are inexpensive and catch problems early.

Water hardness across the metro varies. In neighborhoods with harder water, mineral deposits can glue the mounting ring and the sink flange over time. When I’m called for Garbage disposal repair in those homes, I often find a crust of calcium around the tailpiece threads. A thin smear of plumber’s grease on the gasket surfaces during installation makes future service easier without compromising seals.

Storm season brings power dips. A disposal mid-cycle during a brownout can stall and trip its internal overload. If a homeowner reports dead behavior after a storm, I ask them to check the under-sink GFCI or the panel breaker and then try the reset button. If the unit hums but won’t spin, it’s likely a jam rather than a burned motor.

Knowing when to repair and when to replace

A good disposal lasts 7 to 15 years depending on use, model, and water conditions. If the housing is cracked or the motor bearings scream, replacement makes sense. Leaks at the sink flange or discharge connection are usually fixable. A leak from the body of the unit often means corrosion has eaten through, especially on older aluminum housings. That’s a replacement. For an Affordable garbage disposal repair, the best candidates are electrical resets, jam clears, replacing a worn splash guard, or swapping a failing stopper assembly. If the unit vibrates violently, check for a bent impeller or a foreign object. Sometimes a nickel stuck under a shredder ring causes drama that looks like end-of-life but isn’t.

Homeowners often ask if upgrading horsepower will solve clogs. It won’t if the drain geometry is wrong. Fix slope and trap height first. A 1/2 HP unit with proper plumbing will outperform a 1 HP unit shoved into a bad trap setup.

If you live in an older home inside the Loop and your circuits are a patchwork of generations, a Kitchen disposal repair Houston service call should include a meter check on the circuit, not just a wrench on the plumbing. A weak neutral or a shared multi-wire branch with a missing handle tie can cause intermittent trips that look like a failing motor.

Costs, contractors, and what to expect in Houston

Prices vary by neighborhood and scope. A straightforward swap with no plumbing or electrical changes often lands in a predictable range for labor. Add a GFCI receptacle or rework the trap, and the price climbs modestly. Lowering a wall stub, running a new circuit, or adding an air gap through a granite counter moves the job into day-rate territory and may involve two trades.

When you hire, ask if the contractor is licensed for the trade involved and whether they will pull a permit if required. In a kitchen remodel, the general contractor usually handles permits, and the subs perform under that umbrella. For a single-trade call, a licensed plumber or electrician can handle their portion. Beware of anyone eager to cut off a plug and twist wires together inside the cabinet without a box. That shortcut shows up later as heat damage on the cord or intermittent outages.

If you prefer to start with repair rather than replacement, look for a technician experienced in Garbage disposal repair across multiple brands. Light grinding noise, slow draining through the disposal, and odors each have different root causes. A reputable Affordable Garbage disposal repair visit should include a trap cleanout, a check of the splash guard, and a test of the motor amperage under load. That tells you whether the unit has life left or is drawing too much current and heading for failure.

A few edge cases worth calling out

If you have a farmhouse sink with a deep bowl, the added depth can force the disposal’s outlet below the wall stub height. Plan for an offset flange or a shallow trap. Some farmhouse sinks also flex more than a metal sink when loaded with water and dishes. Over-tightening the mounting ring can crack thin ceramic. Support the sink correctly and tighten in stages.

Double-bowl sinks complicate the drain geometry. A typical layout puts the disposal on the small bowl with a baffle tee connecting to the larger bowl, then into a single trap. Avoid running two traps. If you install the disposal on the main bowl, you may need a different baffle tee to prevent crossflow. Keep the dishwasher drain on the disposal side, not the opposite bowl, to reduce grease migration.

Septic systems near the outskirts of Houston add another layer. While disposals are allowed, frequent use increases solids load in the tank. If you are on septic, I advise limiting disposal use to soft scraps, avoiding grease entirely, and scheduling pump-outs on the earlier side of your normal interval.

Keeping it code-compliant without overcomplicating life

Disposals retire early when they sit on bad plumbing or marginal wiring. Codes exist to prevent those early failures and to reduce hazards you can’t see. The practical takeaways for Houston kitchens are stable:

- Plan for the geometry under the sink, not just the brand you like. Measure before you buy.

- Respect GFCI rules and make clean electrical connections with the right hardware.

- Route the dishwasher drain with an air gap where possible or a secured high loop, and confirm the local inspector’s expectation if you pull a permit.

- Avoid flex drain hose and double traps. Keep the trap at the right elevation and the arm sloped.

- Test with water under pressure and with the motor running. Recheck after an hour.

Those habits reduce callbacks and keep the under-sink space dry. If you run into something odd, ask. Houston inspectors are generally approachable, and local supply houses hear about code interpretations daily. When in doubt, bringing in a pro who handles Garbage disposal installation Houston wide can be cheaper than a second round of parts and a morning lost to a small leak. And if your unit starts acting up, a focused visit for Garbage disposal repair can extend its life without a full replacement.

The disposal is a modest appliance, but it lives in a complex neighborhood. Give it proper plumbing, safe power, and a little respect, and it will run quietly in the background while your kitchen takes center stage.

DYZ Plumbing, LLC

Address: 1220 Blalock Rd, Houston, TX 77055

Phone: (832) 877-9600