Kitchen Disposal Repair Houston: Quiet and Efficient Operation

A good garbage disposal is one of those unsung kitchen workhorses you forget about until it roars, jams, or quits mid-prep. In Houston, with its humid climate, heavy cooking culture, and older housing stock in neighborhoods like Montrose and the Heights sitting alongside newer builds in Katy and Cypress, disposals see a wide range of use and abuse. I’ve repaired units that chewed through three chicken bones a night for years and others that corroded early because they sat unused in rental properties. Quiet, efficient operation is possible, but it takes the right equipment, careful installation, and a few habits that respect what is essentially a small, high-torque grinder under your sink.

This guide draws on years crawling under Houston sinks, from townhomes connected to aging cast-iron stacks to newer suburban homes with bright PVC runs. You’ll find practical advice on diagnosing noise and performance issues, what matters in a quiet unit, how to decide between repair and replacement, and what to expect from garbage disposal installation Houston wide. If you need Affordable Garbage disposal repair, you’ll also see where a simple service visit can solve the problem without a full swap.

Why disposals get loud, inefficient, or both

Noise and poor grinding usually share a root cause: imbalance, wear, or installation shortcuts. The humming, rattling, or grinding you hear is either the motor struggling or the chamber punishing itself. I’ve opened units where a nickel sat wedged for months, and others where rubber baffles had stiffened like tire treads, food waste disposer troubleshooting turning the sink into an amplifier.

Common culprits include dull or seized grind components, loose or misaligned mounting assemblies, motor bearings wearing out, improper discharge piping that transmits vibration through the cabinet, and worn splash guards that let sound and water spray upward. On Houston service calls, I also see scale and sediment build-up from areas with harder water along the Energy Corridor and in parts of Spring Branch, which increases friction and shortens lifespan.

When a disposal goes loud, energy use can creep up too. A struggling induction motor draws more current while doing less work. You might not notice the electricity cost on one meal, but over months the inefficiency shows up as heat, noise, and shortened motor life.

What quiet actually sounds like

People often ask for a “silent” disposal. Silent isn’t realistic, but you can get to a low, steady hum with a gentle, consistent grind noise that doesn’t carry into the living room. On a properly installed premium unit with a good sink, I expect conversational voices at the countertop to remain comfortable without raised volume. If you hear a sharp clatter, a metallic ping repeating in rhythm, or a choppy rev-up and slow-down, something’s off.

Quiet performance depends on more than the unit. Stainless sink thickness matters a lot. A thin 22-gauge sink behaves like a drumhead. A 16 or 18-gauge sink with sound-deadening pads can cut perceived noise dramatically. In an older River Oaks bungalow with a thin sink, we added a composite mount ring, replaced the splash guard, and coupled the discharge with a rubber connector. The same disposal dropped from an irritating rattle to background noise you’d ignore after two seconds.

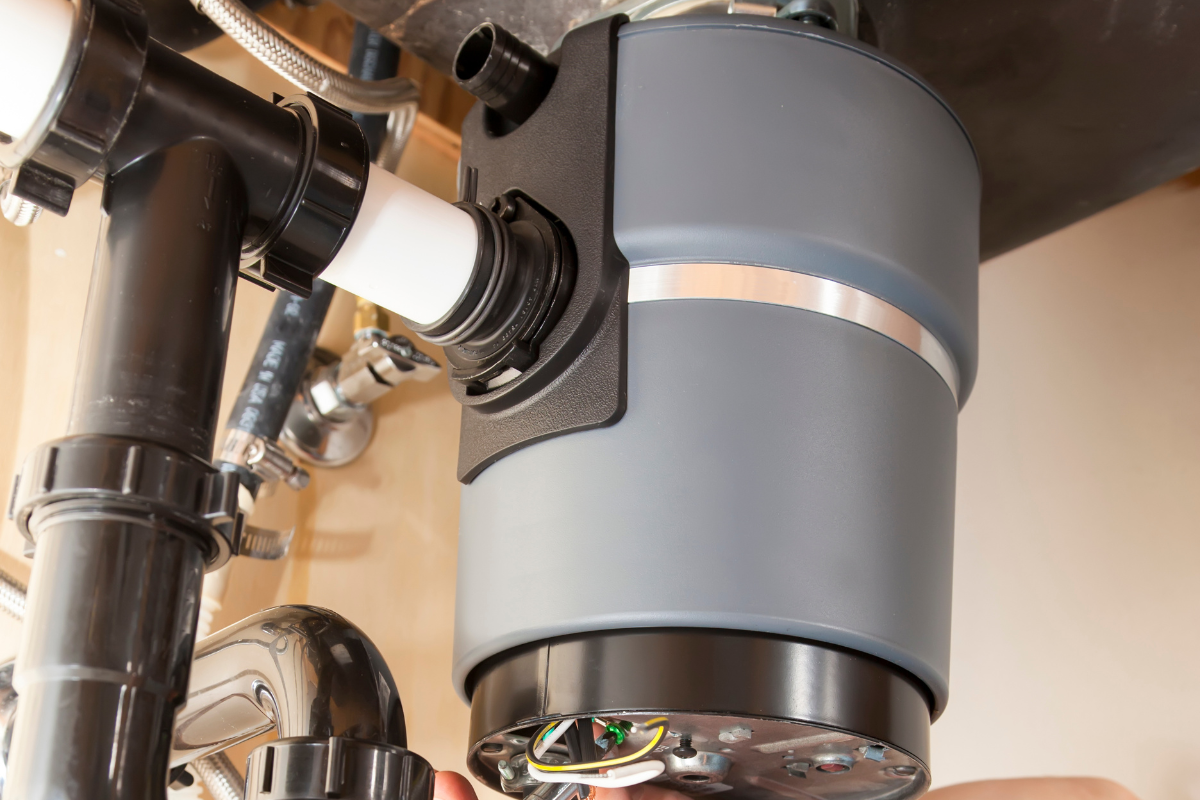

Anatomy of a well-behaved disposal

Not all disposals grind the same. Most modern residential units use an impeller and grind ring in a continuous feed design. The table stakes for quiet, efficient operation look like this:

- An induction motor rather than a universal (brush) motor, which reduces high-frequency whine and usually lasts longer.

- Stainless steel grind components for corrosion resistance in humid cabinets, especially along the Gulf where salt air creeps inland.

- A full sound shell around the motor and chamber, sometimes called SoundSeal or similar.

- A properly sized rubber splash guard layered to absorb vibration and block spray.

- Balanced impellers and a tight mount to prevent wobble.

On the electrical side, a dedicated 15- or 20-amp circuit with clean connections avoids voltage drop and strain. Mechanically, a straight discharge run with a gentle slope to the P-trap reduces turbulence and clog risk. Under-sink slopes that run uphill or include unnecessary 90-degree turns can make even a premium unit feel weak.

Repair or replace: how to decide

I ask three questions on a Kitchen disposal repair Houston call before recommending a path.

First, age and model. If your unit is under five years old, mid to high tier, and the motor still spins freely, it is usually worth repair. For entry-level units beyond seven years, replacement is often smarter. The improvement in noise, grind quality, and stall resistance makes the upgrade feel worth it immediately.

Second, symptoms and severity. A leak at the sink flange gasket is repair territory unless the housing itself has cracked. A jam with humming but no grinding often resolves with an Allen wrench reset and a debris clearing. A motor that hums and trips the breaker consistently, even after a manual free-up, often indicates winding damage or seized bearings which points to replacement.

Third, total cost of ownership. If a repair requires several parts and two hours of labor, the bill can approach the cost of a new quality unit. In a west Houston home last August, a client faced a leaky lower seal and a cracked discharge elbow on a decade-old disposal. The repair would have been within a hundred dollars of a new, quieter model. We installed the new one, added a better splash guard, and the client gained both quiet operation and a fresh warranty.

When I advertise Garbage disposal repair, I mean an honest look at these trade-offs. The most Affordable Garbage disposal repair, long-term, is the one that keeps you off the merry-go-round of callbacks and clogs.

The quiet install checklist that actually matters

Noise reduction is a system, not just a product spec. Whenever I handle Garbage disposal installation Houston homeowners request, I run through a simple checklist that pays off in both sound and performance.

- Match unit size to sink and cabinet. A compact, insulated unit often fits tight spaces without contacting wood walls that can transmit vibration.

- Use a high-quality sink flange and mount. A sloppy mount rattles at startup and shutdown, and can loosen with time.

- Replace the splash guard if it is stiff or torn. New disposals sometimes ship with generic guards that roar. The right guard can make a unit feel half as loud.

- Add a flexible rubber discharge coupling. It decouples vibration from rigid PVC, which otherwise turns the drain line into a soundbar.

- Secure plumbing and electrical, but avoid hard contact points. A power cord draped over the motor housing can buzz like a tuning fork.

This is one of the two lists in the article. Everything on it can be done in one visit. The difference is immediate.

Common Houston-specific trouble spots

The city’s mix of soil types, flood history, and older building materials shows up under the sink. After heavy rains, I have seen minor sewer gas pushback amplify disposal odors in homes Houston garbage disposal services with shallow, partially blocked traps. In pre-1990 homes with cast-iron branches, interior pipe scale can trap fibrous foods that slip through the disposal. In newer developments where the builder used economy-grade sinks, the acoustic performance leaves a lot on the table.

Another recurring issue is the air gap or dishwasher connection. If the dishwasher discharge hose sags, greasy water can trap in the low spot, then burp back. That creates both noise and a smell the disposal gets blamed for. Securing the hose in a proper high loop and ensuring the knockout plug is fully removed on install prevents this.

Heat and humidity shorten the life of rubber components. In garages turned into kitchens, or in homes with under-sink heat from hot water lines running close to the disposal body, splash guards and gaskets harden faster. I recommend a periodic check and replacement every two to three years in these environments to maintain quiet operation.

Troubleshooting at home before you call

Safety first. Always cut power at the switch and, if you plan to reach inside, pull the plug or trip the breaker. With that in mind, a few homeowner steps can save a service call.

Start by looking down the throat with a flashlight. If you see a metal tab, bottle cap, or a peach pit, remove it with tongs. Never with fingers. If the unit hums but does not spin, insert the Allen wrench in the bottom center recess and work it back and forth until it turns freely. Press the red reset button and test.

For odors, ice cubes with a small amount of coarse salt can help, as can citrus peels in moderation. Avoid bleach. It can stiffen rubber and accelerate corrosion in some housings. If noise persists after these steps, the issue is likely deeper: worn bearings, misaligned mount, or a cracked grind ring. That’s the time to schedule Garbage disposal repair with someone who brings both parts and a torque meter, not just a new flange.

What I look for during a professional repair

When I arrive for Kitchen disposal repair Houston customers request, I start with a quick triage. Is the mount tight? Are the electrical connections clean and secured with proper wire nuts or push-in connectors rated for the gauge? Any scorch marks, moisture, or signs of previous leaks?

I check endplay on the motor shaft by hand to gauge bearing health. There should be minimal wobble. I rotate the grinding plate to feel for friction points. If the unit spins smoothly and the housing is solid, I move to the plumbing. A misaligned or overly long tailpiece can transfer vibration. Traps with internal ridges, found in some cheaper kits, can amplify both turbulence and noise.

On older units that leak at the lower seal, you can replace the seal if parts are available and the motor is healthy. But if rust sits visible around the lower housing, a new seal is usually a short-term fix. I discuss that trade-off openly. Some clients only need a few more months before a kitchen remodel, in which case a stopgap repair makes sense. Others want five quiet years ahead, so we install a new unit suited to their cooking style.

Picking a disposal that runs quiet without babying it

The best choice depends on household habits. A three-person family that cooks most nights but avoids bones can do well with a midrange, sound-insulated, 3/4 horsepower unit. These deliver strong torque and quiet operation without the bulk and cost of top-tier models. In homes where guests toss anything down the sink during game days, a 1 horsepower unit with stainless components and advanced vibration control reduces jams and protects the plumbing.

Pay attention to the splash guard design. Some brands offer different guard thicknesses. Thicker guards reduce sound but can slow drainage slightly. I prefer a medium guard for most sinks. If your sink tends to back up because of a shallow basin or slow drain lines, that detail matters.

Also look at the mount system. Quick-lock rings make maintenance easier. If you are upgrading from a builder-grade unit, take the opportunity to swap the flange and ring rather than adapting to the old one. I’ve seen more noise improvement from a solid mount than from brand-to-brand jumps in the same price class.

Installation details that separate quiet from merely new

The devil lives in clearances and contact points. A large disposal crammed against a cabinet wall will telegraph vibration. horsepower 1/2 HP 3/4 HP 1 HP Aim for at least a finger’s width gap around the housing. If you must place the unit close to wood, a thin rubber pad adhered to the cabinet wall can help.

The sink flange needs an even bead of plumber’s putty and a proper torque sequence. Over-torque on one side leads to a slight tilt that causes the grinding plate to ride off-center. I tighten in quarter-turn increments, checking by eye that the flange sits level. For stainless sinks, I clean the underside thoroughly so the putty seals well. For stone sinks where silicone is appropriate, I let the bead cure to the tacky phase before final tightening to avoid squeezing out the entire seal.

Finally, the discharge. A tiny misalignment can add a chatter you hear as a buzz. I cut the tailpiece to length, dry-fit the P-trap, then add the rubber coupling between the disposal and the hard pipe. Tighten until snug, not so hard it deforms. Over-tightened clamps can create an oval shape that whistles under flow.

Everyday habits that keep disposals quiet and efficient

A disposal is more forgiving than a chef’s knife, but good habits still matter. Feed waste in small batches with cold water running before and after. Cold water solidifies fats so they grind smaller and ride the pipe out. If you do toss bones, keep them small. I avoid fibrous peels like celery and artichokes unless they are chopped. Rice and pasta can be fine in modest amounts, but they swell in traps and combine with grease to create plugs. Once a week, a minute of grinding with a few ice cubes helps clean the grind ring. Once a month, lift out the splash guard and scrub it. That one step cuts noise from flapping and removes the primary source of drain odors.

The second and final list in this article is a short no-go set: coffee grounds by the cupful, egg shells in large quantities, potato peels in long strings, and any stringy husk like corn silk. Your plumbing, not just the disposal, will thank you.

What “affordable” really means in disposal service

I hear Affordable Garbage disposal repair used to imply the cheapest upfront price. In practice, affordability means the right fix at the right time. A professional who spends 20 extra minutes leveling a flange, swapping a stiff splash guard, and isolating the discharge with a rubber coupling saves you hours of resonance and callbacks later. If your budget is tight, be honest about it. Good techs can prioritize high-impact fixes and schedule follow-ups.

For a straight repair, most Houston homeowners see labor charges that reflect an hour to ninety minutes onsite, plus parts. Complex pipe adjustments or subfloor access can add cost. For full replacements, the difference between a noisy base model and a quiet midrange unit is often a modest bump relative to total installed cost. You’ll live with the sound daily, so spending a bit more here has outsized value.

When installation quality matters more than brand

Brand debates fill forums, but after hundreds of installs, I care more about how a unit is mounted, coupled, and powered than what logo sits on the grind chamber. Even premium disposals sound awful under a thin, unsupported sink with a crooked flange. Conversely, I’ve made budget units acceptable by pairing them with a robust mount and a smart discharge setup. That said, if quiet is your top priority, choose a model with published sound insulation and a solid track record. Ask your installer which units they see the fewest callbacks on in Houston’s conditions. Local experience beats spec sheets.

Signs it’s time to move from repair to replacement

If your disposal leaks from the bottom housing, emits a burnt smell, or trips the reset repeatedly despite clear water flow and no jam, replacement is likely. If noise changed suddenly after a hard object went through and the sound never returned to normal, internal damage may have occurred. When we open units and see pitting or a wobbling plate, I recommend moving on. The replacement restores quiet and prevents the midnight flood that ruins a cabinet base.

For older homes, replacing the disposal can be a good moment to address under-sink layout. A compact, quiet unit can free space for a pull-out trash bin or water filter, provided you maintain proper trap height and venting. Small design tweaks now avoid wrestling with cramped plumbing later.

Working with a Houston pro

Whether you’re in Midtown with limited access and valet-only parking, or in Sugar Land with a spacious garage and easy tool staging, a good installer adapts. Ask a few simple questions before booking Garbage disposal installation Houston services. Do they replace splash guards by default? Will they level the flange and check drain slope? Can they provide options in writing so you can choose between a straightforward repair and a noise-optimized install? If the answer is yes, you are likely to end up with a disposal that hums quietly through dinner prep and stays that way.

Schedule service when someone is available to run water tests with the tech. It takes five minutes to run the dishwasher in rinse mode, fill the sink, release, and listen. Real-world testing catches problems a dry install can miss.

A final word on quiet that lasts

Quiet and efficient operation is not a one-time achievement. It comes from choosing the right unit, installing it with careful attention to vibration paths, and maintaining a few simple habits. Houston kitchens ask a lot from disposals, with heavy cooking, varied plumbing, and the area’s heat and humidity. With smart choices and a bit of vigilance, your disposal will fade into the background where it belongs. When it doesn’t, a focused Garbage disposal repair is often all it takes to bring it back, and when it’s time for a new unit, a thoughtful installation turns a small appliance into a reliable, quiet partner in your kitchen.

DYZ Plumbing, LLC

Address: 1220 Blalock Rd, Houston, TX 77055

Phone: (832) 877-9600