Houston Garbage Disposal Installation: Choosing Horsepower and Size

Walk into ten Houston kitchens and you will probably see ten different personalities living under the sink. Some disposals sound like a jet engine, some hum politely, and a few only rattle out of habit. They are not one-size-fits-all machines. Matching horsepower and chamber size to the way your household cooks makes the difference between a reliable workhorse and a constant source of clogs, leaks, and midnight resets.

I install and service garbage disposals across Houston neighborhoods that cook in very different ways. A family in Spring Branch that hosts crawfish boils needs a different unit than a couple in a downtown high-rise who mostly blend smoothies and reheat meals. The soil under your slab, the age of your home’s plumbing, and even what your HOA allows can nudge the decision. Here is how I approach horsepower, size, noise, and installation for Houston homes, along with pitfalls I see during garbage disposal repair calls and the upgrades that actually pay off.

How horsepower ties to your cooking habits

Manufacturers sell disposals from about 1/3 horsepower up to 1 horsepower and a few heavy-duty models beyond that. The number is not about raw speed, it is torque. In practice, horsepower determines how forgiving your disposal is when a teenager empties a cereal bowl full of wet flakes, or when you feed it stringy celery after making gumbo.

For a smaller household of one or two light cooks, a 1/2 HP unit can be enough. It will handle soft scraps, eggshell bits, and the occasional small chicken bone, though I advise a gentle touch with bones unless the unit is explicitly rated for it. Most 1/2 HP models have smaller grind chambers to keep costs and power draw down. That trade-off saves space in tight vanities, which is helpful in some Montrose bungalows with shallow sink bases.

Families who cook several nights a week and run the sink disposal daily are better served by 3/4 HP. That step up brings stronger induction motors, better anti-jam features, and larger chambers. The improvement shows up when you are processing mixed plates after a weeknight dinner — noodles, rice, vegetable peels — without babying the feed. In my experience, 3/4 HP is the sweet spot for many Houston homes because it balances price, performance, and noise control.

For big households or avid cooks who tackle tougher waste — think husks after a tamales day, melon rinds, or the remains of a backyard barbecue — 1 HP is where the machine starts to feel effortless. These units typically have stainless steel components throughout, better sound insulation, and longer warranties. The added torque reduces stalls, which means fewer service calls for jammed rotors. If your sink drains slowly or your pipes have a history of clogs, more horsepower is not a cure-all, but it helps the disposal push through grind cycles quickly so waste exits the chamber before it can settle.

A quick rule, tuned to Houston kitchens I see every week: apartment or condo with modest cooking, 1/2 HP; single-family home with regular cooking, 3/4 HP; large family or frequent gatherings, 1 HP. Within those buckets, the brand and model quality can matter as much as the number printed on the box. During garbage disposal repair visits, I often find a budget 3/4 HP with lackluster components can perform worse than a well-built 1/2 HP from a reputable line.

Chamber size, grinding stages, and what they mean day to day

Horsepower tells you force, but the chamber tells you capacity and tolerance. Two features matter most: the volume of the grind chamber and the number of grinding stages.

A larger chamber gives food more room to circulate and mince down evenly. That means less chance of a wad of fibrous waste pinning the turntable. In tight sink bases, a smaller chamber can buy you space, but do not undersize to the point where routine use becomes a chore.

Grinding stages refer to how many passes the waste makes through cutting and shearing surfaces inside the unit. Single-stage disposals crush food once. Multi-stage units, common in higher-end 3/4 HP and 1 HP models, use secondary rings or shears to further reduce particle size. In older houses with cast iron or galvanized drain lines, which can build internal roughness, finer grind is a real benefit. Smaller particles travel farther before snagging. I have cleared enough 1960s-era pipes in Oak Forest to know that multi-stage grinds help prevent the recurring slow-drain complaints that prompt Kitchen disposal repair Houston calls.

Noise ties closely to both chamber size and build. Larger, better-insulated housings with rubber mounts absorb vibration. If your kitchen opens to a family room, look for sound ratings or models known to be quiet. Insulation does add bulk, so measure carefully when you have pull-out trash cans or water filter canisters sharing the space.

The Houston plumbing context: traps, vents, and code quirks

Local conditions matter. Many Houston homes have slab foundations, and it is common to see long runs of 1.5 inch drain lines from the kitchen to the main stack. Those runs can be flat or even back-graded by a quarter inch over 10 feet if the home has settled. A disposal that pulverizes food more finely makes a difference in marginal slopes.

Traps and air admittance valves also affect performance. A disposal discharges water and waste quickly, which pulls a brief vacuum behind it. If the line is not vented properly, that vacuum slows the flow and encourages solids to drop out. I see this in garages converted to kitchens without traditional roof vents. In those cases, adding or replacing an AAV and testing it during Garbage disposal repair can make a 1/2 HP unit behave like a stronger machine simply because the line stays moving.

Dishwasher connections are another regional note. Builders often connect the dishwasher to the disposal inlet because it is convenient and legal when you add a high loop. If you install a disposal with a smaller throat or forget to knock out the dishwasher plug, you will have a brand-new unit that backs up rinse water into the dishwasher. I still get two or three calls a month where the only fix is a slug with a screwdriver and a quick flush.

Finally, ensure your under-sink GFCI setup matches the disposal load. Most units draw between 4 and 8 amps, with a brief surge at startup. A dedicated switch-controlled outlet is ideal. If you are trying to share a single GFCI with a high-end disposal and a powerful dishwasher, nuisance trips become a theme. When we handle Garbage disposal installation Houston wide, we often correct the circuit layout while we are there. It costs a bit more that day, and saves a string of frustrating resets.

Space, sink design, and the ergonomics of living with the unit

The practical details of the cabinet are easy to overlook when you focus on horsepower. A deep farmhouse sink with a standard flange can eat up vertical room, leaving little clearance for a tall 1 HP motor. Most disposals need between 12 and 16 inches of vertical space from the bottom of the sink to the cabinet floor. If you have a reverse osmosis tank, a fire extinguisher, and a trash pull-out sharing the cabinet, choose a more compact disposal and a solid 3/4 HP unit over a bulky 1 HP.

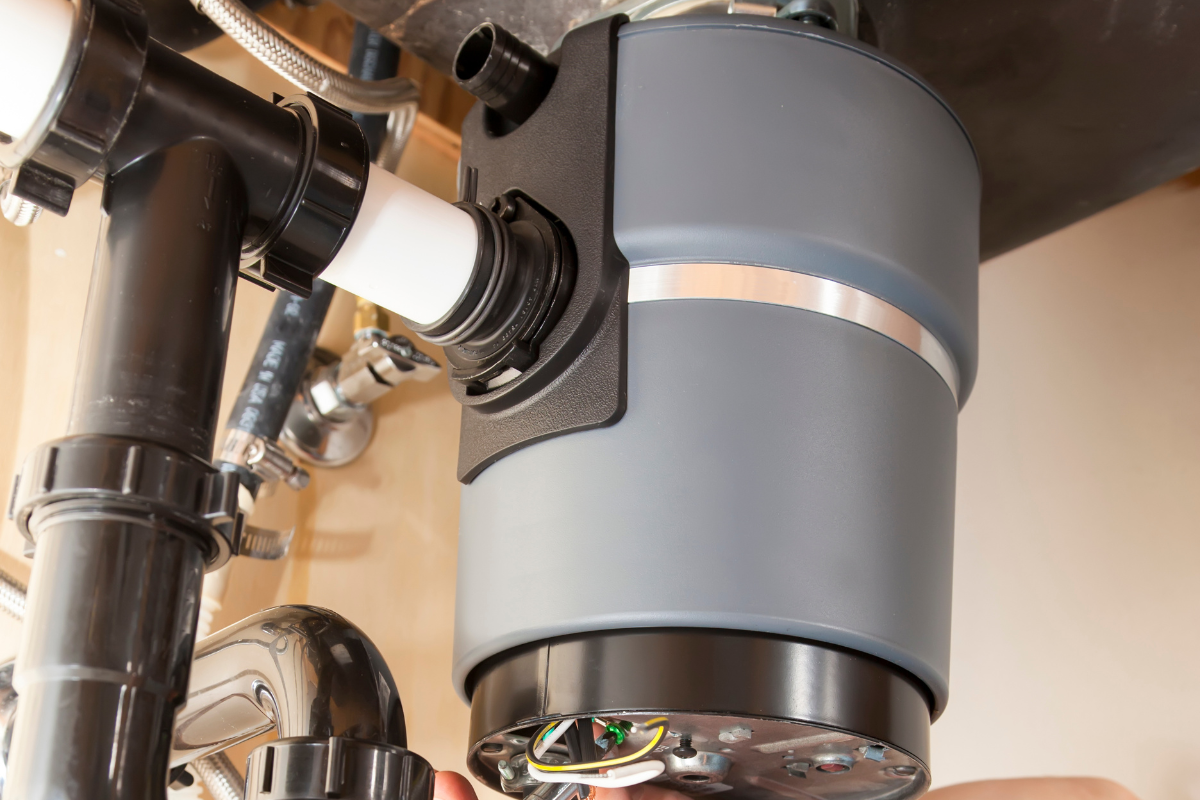

Mounting matters too. Many modern units use a quick-lock three-bolt mount that allows easy replacement without changing the sink flange. That saves labor during future Garbage disposal repair or replacement. Some boutique sinks require proprietary flanges, which can lock you into certain models. Bring the brand and model of your sink to the selection process, especially with composite or fireclay sinks, which sometimes need a wider or reinforced flange to prevent cracking and leaks.

The baffle in the sink opening plays a role in daily comfort. A tight baffle keeps noise down and limits splashback, but it can slow water flow. If you do a lot of pasta and rice, a slow-draining baffle encourages the very clumping that leads to clogs. I keep a couple of alternate baffles in the truck for customers who want to tune that trade-off after living with a new unit for a week.

What I tell clients about what not to grind

Every city has its culinary hazards. In Houston, we meet rice and pasta clogs more than coffee grounds or corn husks. Rice swells and tacks to the inside of drain lines if you send it in the disposal without plenty of water. Pasta makes long gluey strings that net across the trap. No horsepower solves poor habits here. Run cold water at a steady flow before, during, and after grinding, and feed starches gradually. With crawfish or shrimp shells, the occasional handful is fine in a 3/4 HP or larger unit with stainless grind parts, but a half pot of shells goes to the trash every time.

Fibrous peels like celery, leeks, and pineapple threads wrap around the turntable and trip thermal overloads. Citrus peels make the kitchen smell like a hotel lobby, which is nice, but limit the volume to a few strips at a time, and avoid oversized pithy rinds. Bones are okay in brief cameos for robust models, but bone-heavy loads belong in the bin. If you compost, let the disposal handle the scraps that would otherwise stink in the can during August heat, and keep volume reasonable.

Installation notes that avoid the callback

A clean installation starts at the flange. Use the right seal for your sink material. Putty is still the standard for stainless steel sinks, while many composite and porcelain sinks prefer a gasket to avoid staining or stress. Tighten evenly. I often see leaks from over-torqued flanges that warp the sink lip. Spot check after the first day by filling the basin and letting it sit for a few minutes, then inspect the cabinet floor for a ring of moisture.

Set the discharge height to keep a proper fall to the trap. Too high and you create a cradle for solids. Too low and you may siphon the trap, pulling odors back into the cabinet. Your trap arm should have a gentle slope, roughly a quarter inch per foot, toward the wall. Dry fit first, then cement. A light smear of silicone on slip-joint washers helps avoid drips without cranking the nuts so tight that they crack.

Wire the unit according to the manual. Some disposals come with a cord, others need a hardwire connection inside a covered junction box. If you are uncomfortable working with household wiring, bring in a licensed pro for an hour. Loose connections make heat, and heat under a wood cabinet is not worth the risk. The switch should break the hot leg, not neutral. Label the breaker so the next person who services the unit does not guess.

Knock out the dishwasher plug only if you have a dishwasher line to connect. Once you remove it, there is no going back without replacing the inlet assembly. After you connect the dishwasher hose, secure it with a stainless clamp and confirm you have a high loop to the underside of the counter to prevent backflow into the dishwasher. I pour a half gallon of water through the dishwasher before I leave any job to verify the connection stays dry under real flow.

Noise, vibration, and keeping the family peace

Noise comes from three places: the motor, the vibration of the unit against the sink, and the splash at the baffle. Better units manage all three. Induction motors hum more smoothly than cheap universal motors. Rubber isolation mounts between the disposal and the sink reduce vibration transfer. Some high-end models add a cushioned tailpipe connection to calm the resonance in the drain.

If you want a quiet kitchen, focus on models known for sound insulation and consider adding damping under the sink. A strip of closed-cell foam on the cabinet floor eats a surprising amount of buzz. If the sink itself is thin gauge stainless, adding sound deadening pads helps more than people expect. When I replace builder-grade sinks, I often show homeowners how tapping a bare sink rings compared to one with a pad. That ringing turns into a louder disposal.

Water flow affects tone as well. A strong, steady stream keeps the chamber loaded, which reduces chatter. Trickles make the unit rattle pebbles against the baffle and sound worse than it is.

Maintenance that actually extends life

Disposals fail for a few predictable reasons: corrosion, jams that trip thermal protectors repeatedly, and leaks at gaskets that go unattended. Stainless steel grind components cost more, but shrug off corrosion much longer than plated parts, especially in coastal humidity and with Houston’s variable water chemistry. Running the unit at least a few seconds every couple of days keeps seals lubricated. Long idle periods dry them out, and then the first heavy use leaks into the cabinet.

Clean without being harsh. Ice cubes do not sharpen blades, since disposals do not have blades, but a cup of ice can knock biofilm off the grind ring. A handful of rock salt does the same. Avoid bleach. It hardens rubber and shortens the life of splash baffles. A little dish soap and a stiff stream of cold water after use goes a long way.

If you smell funk, it is usually trapped gunk in the baffle or the upper chamber. Turn off the switch, remove the baffle if it is removable, and scrub both sides. For fixed baffles, pull the power at the breaker and wipe the underside with a bottle brush. If the smell returns quickly, check the trap for a sludge cap and clean it.

What goes wrong most often, and how I handle it

Most Garbage disposal repair calls fall into three categories: jams, leaks, and electrical dead units. Jams are common after big dinners. The unit hums but does not turn. Cut power, use the hex wrench on the bottom to free the rotor, pull out any visible debris with tongs, and try again. If the overload tripped, press the reset button. Persistent jams suggest either a mismatch between unit and usage, or dull, corroded grind components.

Leaks show up at the sink flange, the dishwasher inlet, or the discharge elbow. Flange leaks drip during stand water tests. Inlet leaks show only when the dishwasher runs. Discharge leaks drip during grind cycles. Each points to a different gasket or connection. A slow flange drip ruins particle board floors if left for weeks. I carry replacement fiber gaskets and stainless clamps for quick fixes. When the disposal housing itself cracks, usually after a drop during DIY installation, it is replacement time.

When a unit is dead, I check the simple items first: the reset button, the switch, and the breaker. A dead switch takes five minutes to test with a non-contact pen and a replacement two-way switch. A tripped GFCI under a sink that also feeds the dishwasher is a pattern I see monthly. If the disposal trips the overload repeatedly under light load, the motor windings may be failing. That is when repair gives way to replacement.

For homeowners looking for Affordable Garbage disposal repair, the cheapest solution is preventing avoidable issues. Do not treat the unit like a trash compactor. Give it water. Address early leaks. If the machine is old, and repair costs approach half the price of a new unit with a better warranty, replacement is the value play.

Environmental and utility considerations in Houston

A disposal is not a license to send all food down the drain. Houston’s wastewater treatment plants can handle normal use, but heavy solids increase load. Fats, oils, and grease cause the biggest headaches in sewers and your own lines. Pour them into a can, let them cool, and toss them out. Some neighborhoods still have clay or cast iron mains with vulnerable joints. Fine grind helps, but the best practice is restraint.

Water usage is modest for normal operation, usually a couple of gallons per minute for short runs. Cold water helps grease stay firm and move along rather than liquefy and coat pipes. Power draw is also modest. A typical 3/4 HP disposal uses under a kilowatt hour for a week of typical use in a four-person home. That ranks it low on the list of energy hogs.

If you compost, you can run a smaller unit, since you will only use it for the wet scraps that attract pests. If you do not compost, a well-matched disposal is still kinder to your drains than rinsing plates directly into the trap with no grinding at all.

What to expect on installation day

Most straightforward replacements take about an hour, assuming the sink flange is compatible and the drain lines are in good shape. A first-time install where we add a dedicated switch, a new flange, and adjust the trap can stretch to two to three hours. I bring a drop cloth, a bucket, PVC fittings, and a few types of baffles so we can fine tune the feel. Once installed, we run the unit under load, check every joint for leaks, and walk you through the sounds and cadence of a normal grind.

Scheduling matters if you cook a lot. Pick a morning slot so we can return the same day if a surprise fitting is needed. If the cabinet floor has previous water damage, consider having a new floor panel ready. Nothing sets a homeowner up for trouble like installing a heavy 1 HP unit onto a warped, soft cabinet bottom.

For those looking at Garbage disposal installation Houston services because a DIY attempt went sideways, do not worry. It happens. If a plastic elbow cracked or the old flange will not budge, a pro can usually salvage the situation without replacing the sink. The trick is to stop before over-tightening or prying damages the sink rim.

Brand and warranty considerations without the hype

I avoid naming specific models, since lines change year to year, but a few principles hold. Favor stainless steel internals for durability, especially for 3/4 HP and above. Look for models that list sound insulation explicitly if noise bothers you. Multi-stage grinding is worth it in older houses or longer drain runs. Warranties that cover in-home service rather than carry-in replacements are valuable, since under-sink work is awkward and time consuming for homeowners.

If you expect to replace the unit in five to seven years, a mid-tier 3/4 HP with a leak sensor can be smart. If you want a set-and-forget ten-year run, invest in a 1 HP with full stainless and a longer warranty. The upfront price difference, often in the range of 100 to 200 dollars, spreads thinly over years of daily use.

Matching the decision to your home and habits

You can boil the choice down to a few decisive questions.

- How many people live in the home, and how often do you cook from scratch?

- What is the state of your kitchen drain lines, and how long is the run to the main stack?

- How much under-sink space do you have, including other equipment like filters or RO tanks?

- Do you prize quiet operation, or is performance your priority?

- Are you connecting a dishwasher to the disposal inlet?

Those answers steer you to the right horsepower and chamber size, and to small features that make living with the machine easier, like quick-lock mounts and replaceable baffles. If the decision still feels fuzzy, call a local pro for a brief consult. A good technician will look at your cabinet, trap, and venting, then suggest two or three models clear disposal jam with hex key at different price points. Many of us offer both Garbage disposal repair and new installations, so we see which units keep us out of your hair.

When repair is smarter than replacement

A jam that clears with a hex key, a small leak at a discharge gasket, or a faulty switch repair is quick and inexpensive. If your unit is under warranty and starts tripping the overload after a jam, I will open it up before pushing for replacement. Grinding plates can seize with a single penny or olive pit lodged just right.

Replacement makes more sense when the housing is cracked, the motor overheats under light loads, or the chamber is rusting through. If you are calling repeatedly for the same jam issue and you have already adjusted habits, you probably undersized the unit. At that point, upgrading saves money and sanity. If you are searching for Affordable Garbage disposal repair because of cost concerns, ask for a repair-or-replace quote side by side. An honest shop will tell you when a modest upgrade is the better deal.

A brief word on safety and the reset dance

Never put your hand into a disposal that still has power. Pull the plug or flip the breaker. Use tongs or pliers for foreign objects. Always check the reset button after a jam. If the unit trips immediately again under minimal load, stop and call someone. Repeated resets can mask a failing motor and lead to heat damage.

If a spoon or a bottle cap gets in and leaves the unit noisy even after removal, the grind ring may be bent. That repair is not worth the labor on most models. Replace the unit, and consider a tighter baffle to prevent repeats. Keep the hex key taped to the inside of the cabinet door. The day you need it, you will be glad it is within reach.

Bringing it all together for Houston kitchens

Choosing a disposal in Houston is about more than the sticker on the box. It is your cooking style, the age and slope of your drains, the cabinet space, and the noise level your family can live with. Most homes land on a quality 3/4 HP with a decent chamber and good insulation. Larger households or heavy cooks benefit from 1 HP. Smaller, lighter-use kitchens can lean on 1/2 HP if the plumbing is tidy and habits are gentle.

If you run into trouble, local technicians who handle Kitchen disposal repair Houston wide can usually diagnose and fix jams and leaks the same day. When the time comes for a new unit, pairing sensible horsepower with a right-sized chamber and careful installation avoids the common pitfalls that lead to callbacks. You get a tool that disappears into the background, keeps the sink clear during the biggest meals, and stays quiet enough that the conversation at the counter never needs to pause.

DYZ Plumbing, LLC

Address: 1220 Blalock Rd, Houston, TX 77055

Phone: (832) 877-9600